PLOUGH SHARE MIXER

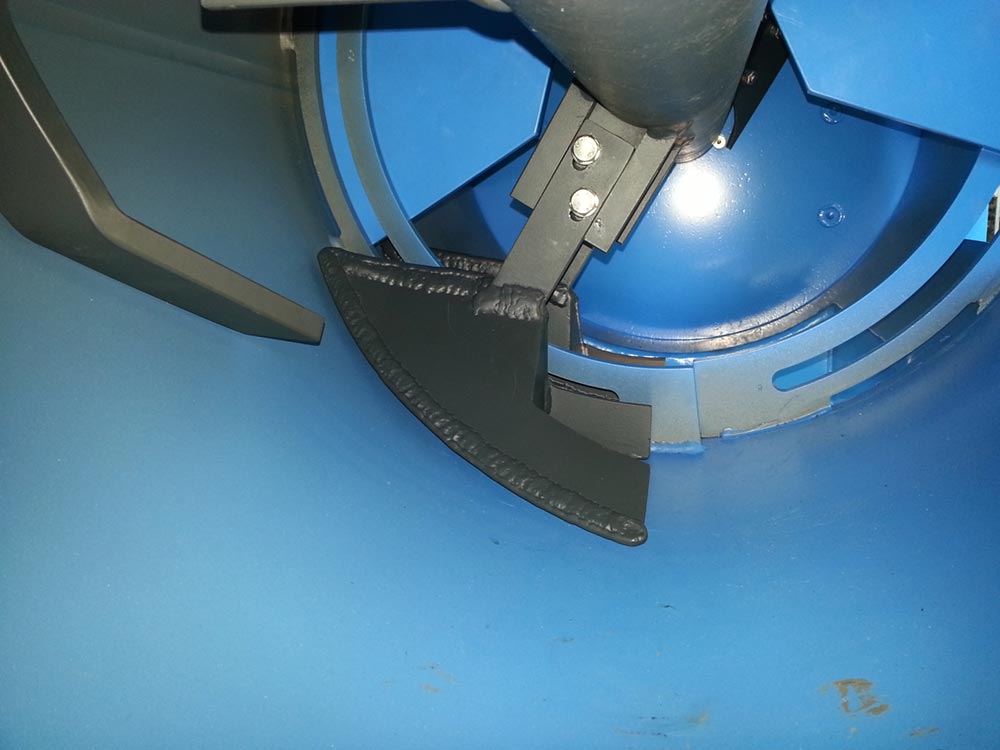

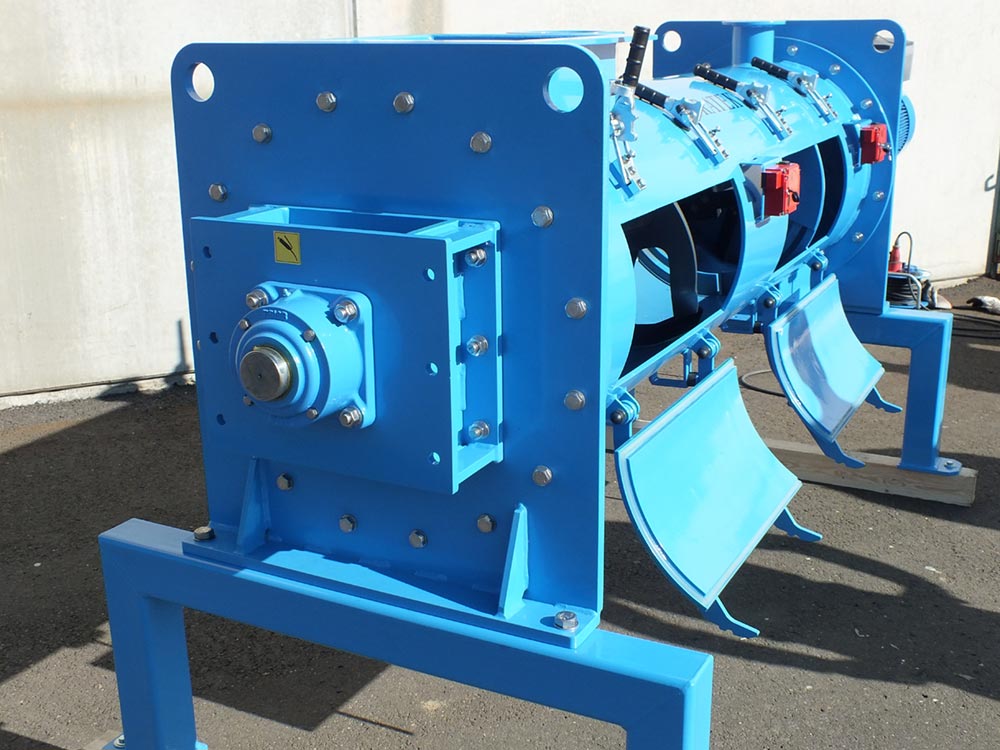

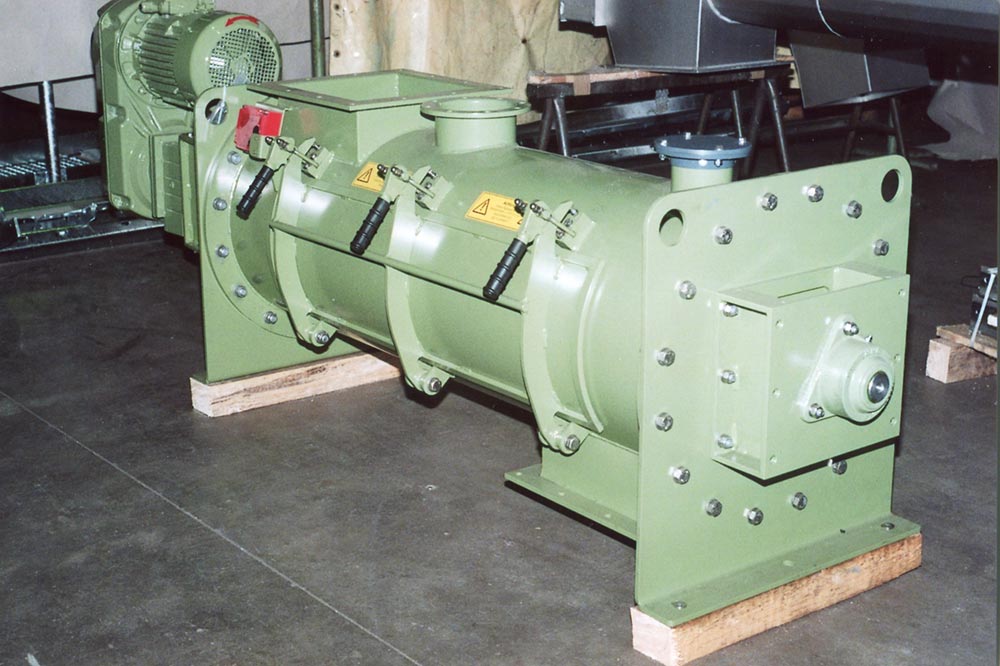

The tools, which are arranged in a staggered order in the horizontally positioned cylindrical mixing drum, rotate on the shaft.

The mixing tools are arranged in a staggered order and rotate on the strong horizontal shaft mounted in the cylindrical mixing drum. Shape and arrangement of the mixing tools force the mixed material to fall down from the drum walls and cause intense mixing. The circumferential velocity of the mixing tools is designed in such a way that the mixed material forms a vortex layer thus creating an optimal turbulence for the mixing process.

The holding time of the mixed material can be regulated by means of an adjustable gate in front of the discharge orifice. For the crushing of agglomerates and lumps, the mixing unit can be equipped additionally with cutter heads which are arranged laterally on the drum wall.

PURATEK plough share mixers can be used for batchwise mixing of:

- dry solid material

- granulate material

- paste-like material

- powdery material

- sludge with solids (conditioning)

Therefore, the areas of application of plough share mixers are as follows:

- disposal industry

- sewage treatment plants

- building materials industry

- chemical industry

- environmental engineering

Main features:

- Highest mixing qualities with short mixing times

-

Simple, compact and rugged design

- High operational reliability and long service life

-

Easy-to-clean mixing chamber and small dimensions of installation

Mixer inlet and outlet openings are fitted with rectangular flanges. The addition of the conditioning agent is effected in a round inlet pipe with flange. Gases are extracted through an additional pipe connection.