COOLED OR HEATED SCREW CONVEYORS

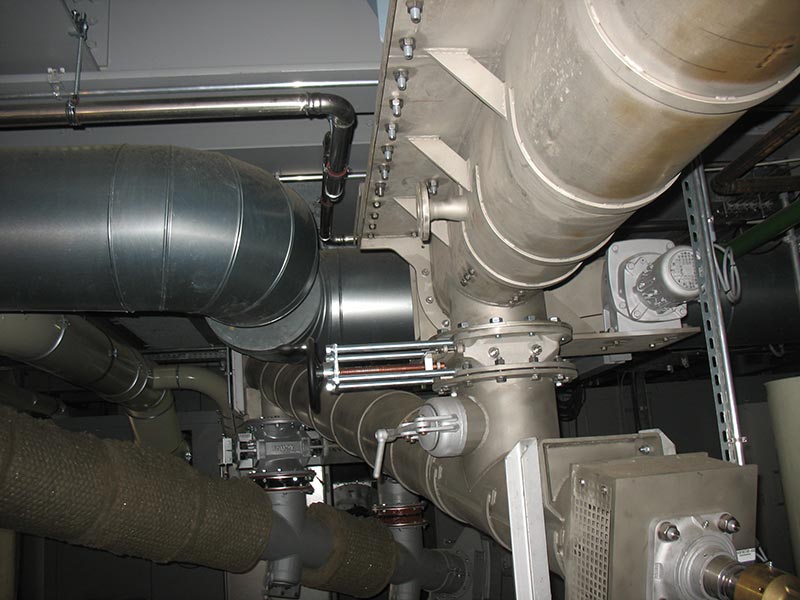

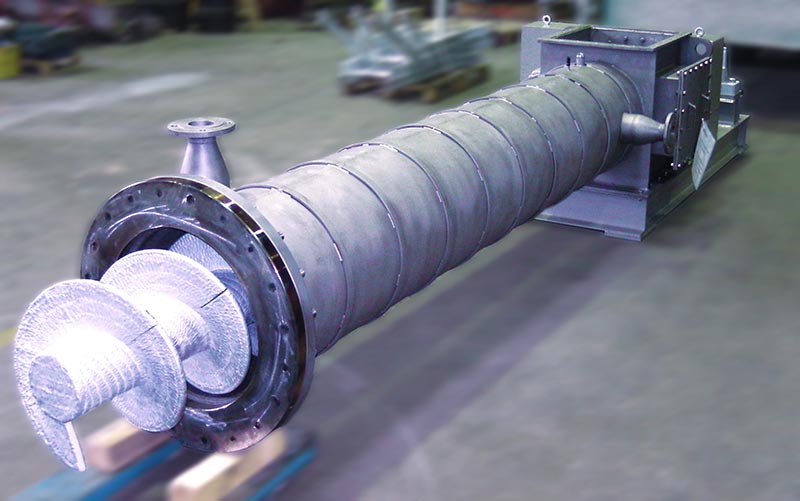

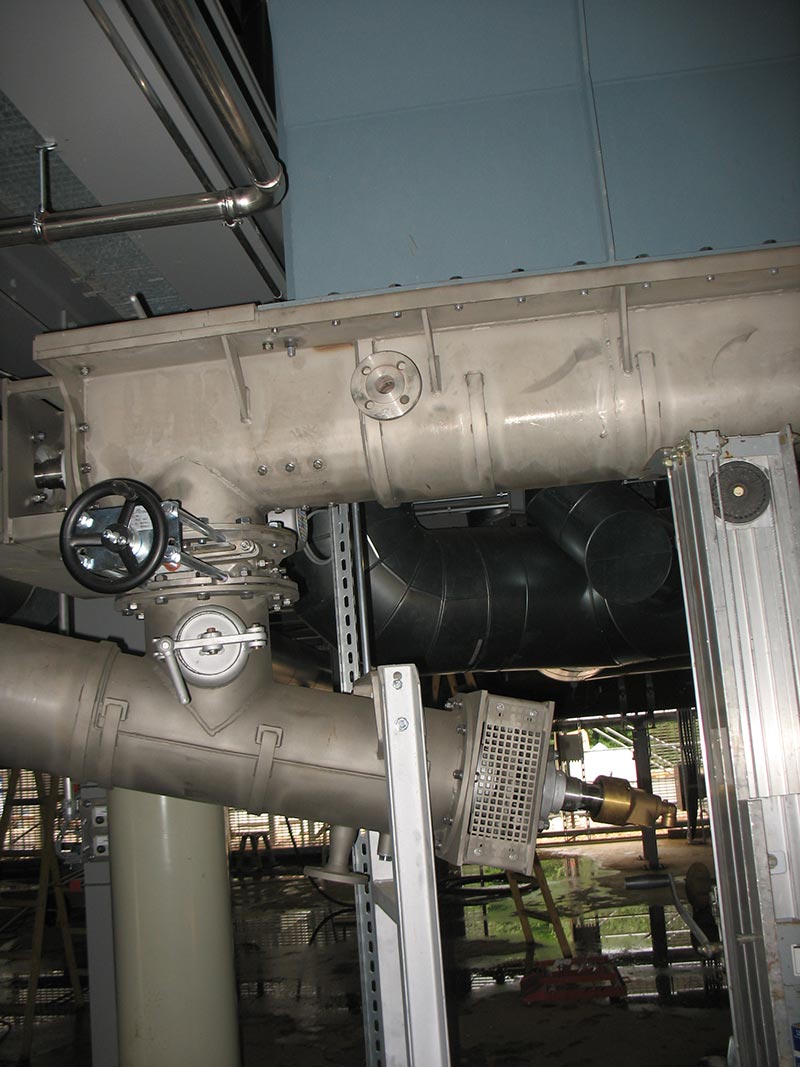

The conveying process often requires the treated materials to be cooled or heated at the same time. The PURATEK-exchange® unit is a conveyor with jacket, shaft and spiral cooling or heating. Especially designed for heavy-duty applications.

The performance-optimized cooled or heated screw unit convinces with a high heat transfer coefficient with a simultaneously high conveying rate. These characteristics are achieved by optimizing the geometry of the conveyor screw unit, thus maximizing the available thermal exchange surface.

The cooling/heating medium is guided in precisely defined and flow-optimized channels. The cooling or heating medium flows through the conveyor/mixer jacket, screw shaft and screw blades. A wide variety of cooling and heating media can be used: water, steam, thermo-oil, Glysantin® mixture, etc.

The layout of the PURATEK-exchange® unit involves the most advanced calculation methods. This is an advantage especially when the cooling or heating screw must operate at narrow space, such as a small temperature difference between the cooled and heated medium.

For corrosive, chemically aggressive and extremely abrasive materials to be conveyed and to be cooled or heated simultaneously, special production materials are used. The PURATEK-exchange® unit is mainly made of high-quality stainless steel up to Duplex steel.