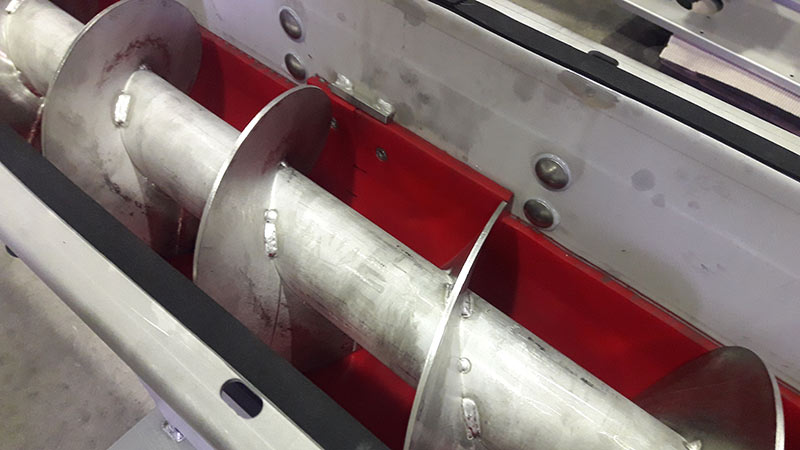

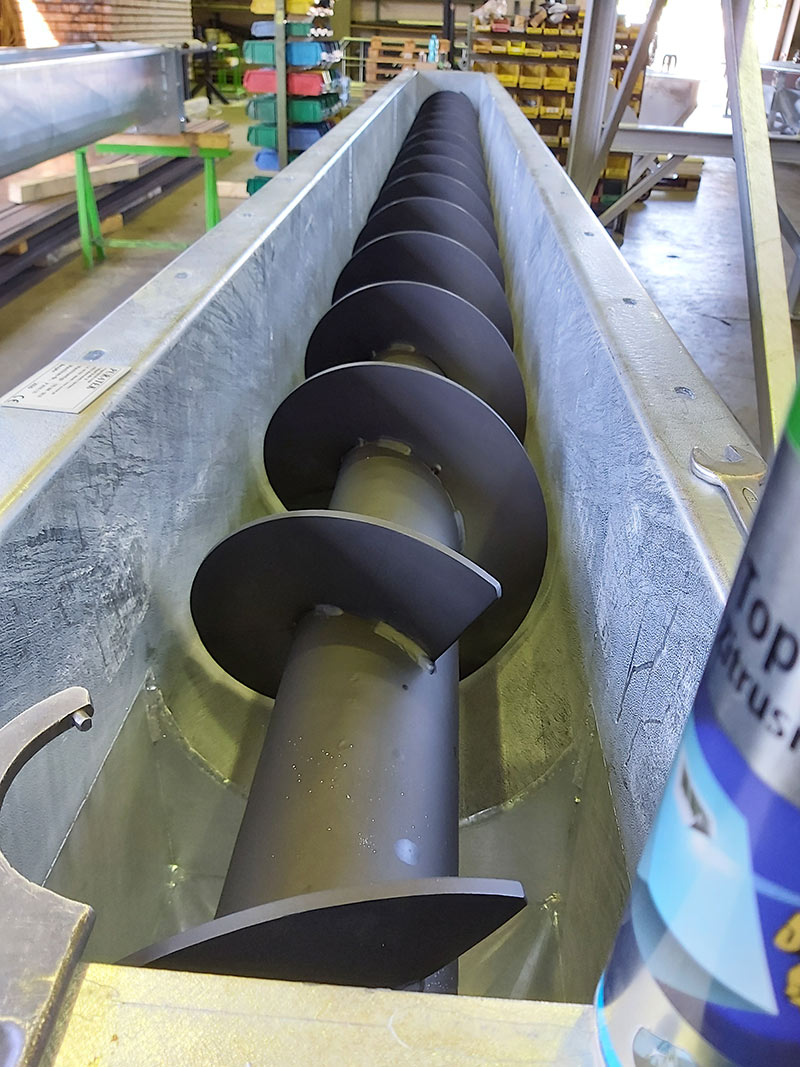

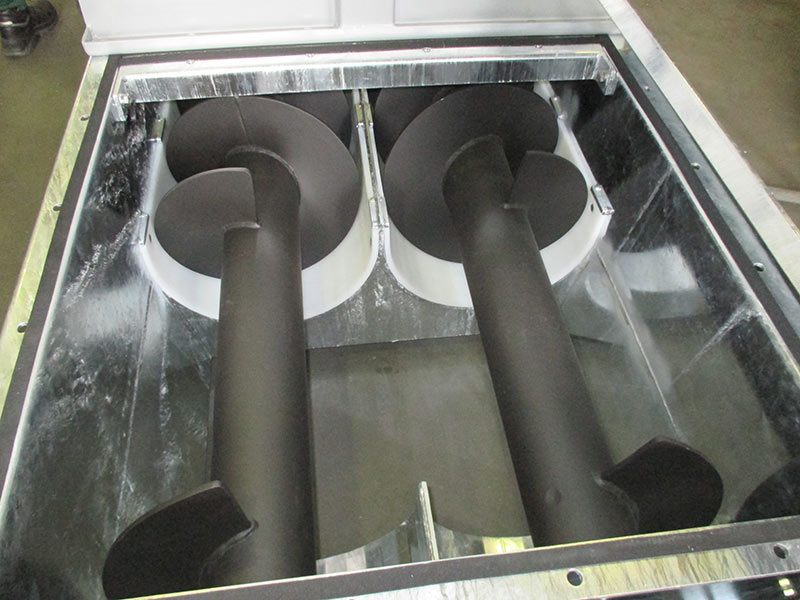

TROUGH SCREW CONVEYORS

TROUGH SCREW CONVEYORS can be installed for a wide range of fine-grained and coarse-grained, dry and wet media to be conveyed in horizontal to steeply ascending positions.

The double-edged, U‑shaped trough in hot-dip galvanized steel or stainless steel with screwed as well as edged cover segments allows easy access to the inner trough for maintenance.

The end walls are bolted to the trough in a watertight manner, the screw shaft is fixed on both sides with external flange bearings and an inspection and maintenance opening is provided above the discharge chute.

The drive can be pulling or pushing, and two dischargers can be operated with a reversible drive. The solid-blade worm spirals are continuously welded to the shaft.

Special designs, e.g. with progressive helix pitch, with shredding cutouts on the outer edge of the helix under the inlet pipe or the installation of replaceable inserts of different material grades, a stationary support or suspension structure or a cantilevered, swiveling loading device, the double-walled design as a cooling or heating screw, etc. are possible at any time.